| Euro Ship Brokers | |

| Leisure & Commercial Boat Brokers, Clyde Boatyard, Dock Street, Clydebank, Dunbartonshire, G81 1YP, UK | |

| Contact: | Shona McColl |

| Telephone: | Reveal Telephone Number |

| Mobile: | Reveal Mobile Phone Number |

| View All Euro Ship Brokers Listings | |

Description

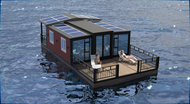

SECTIONAL FLOATING DOCKS.

These Docks are built in Holland and sectional, ship transportable anywhere in world.

Sizes of 500/10,000 tons...

There is One Demonstration Model for around 500 tons which could be for sale.

Specifications

| Constructed: | 2016 |

| Length over all: | 47.4m |

Construction

Lift capacity is from 500 tons upwards, if a problem - draft is variable.

4 x sections around 47.4m, length of sections is variable. Width standard at 15.0m add for overall length of Dock.

Equipment

The Talsma Modular dry-dock system consists of 2 or more modules structurally coupled together in order to let the modules function as one integrated construction. Operation is therefore possible from a single point directing flooding and emerging.

The whole dock. For redundancy reasons and in order to be able to dock every single

Module in the other two, at least 2 modules will be equipped with an independently working blower system. The working principle of the dock is by feeding pressurized air into the ballast tanks. Every tank has a bottom valve to let the water in or out. This means that the water is forced out of the ballast tanks by pressurized air and

Opening of the valves. This enables the dock master to trim the dock in every desired sequence and direction without a complex piping and pump system.

General technical description

• Measurements on request max. Longitudinal length per module is 11,85m.

• Dock floor: S355 type steel

• Paint system: Durable 3-layer 400 micron nom.

• Air system: Double set of Roots blowers

• Ballast flooding system: electrically operated valves per tank

• Effective lift capacity: dependent on the geometry

Standard scope of delivery

• Materials and components for a complete dock as described suitable for classification

• Processing of materials

• Basic design and adjustments

• Production information and engineering

• Load and stability calculations

• All construction work in our factory in Franeker

• Painting

• Galvanized piping and installation

• Mechanical and electrical installation work

• Measurement and welding reporting

• Paint reporting (spec, thickness and circumstances)

• Maintenance and inspection plan

• FAT (factory acceptance test)

• Instruction and training on the dock (in the water) at the yard for one group, 5-days

• Transportation from the yard to the port of Harlingen

Disclaimer

Whilst every care has been taken in there preparation, the correctness of these particulars is not guaranteed.

The particulars are intended only as a guide and they do not constitute a term of any contract.

A perspective buyer is strongly advised to check the particulars and where appropriate to have the vessel fully surveyed and inspected, sea trialled and opened up

Location Map

Note: Indicated location is approximate general area only.